Project Details

- Rob’s house

- 24th March 2020

- Marilin De Aragon

- UI/Ux Design

Project Description

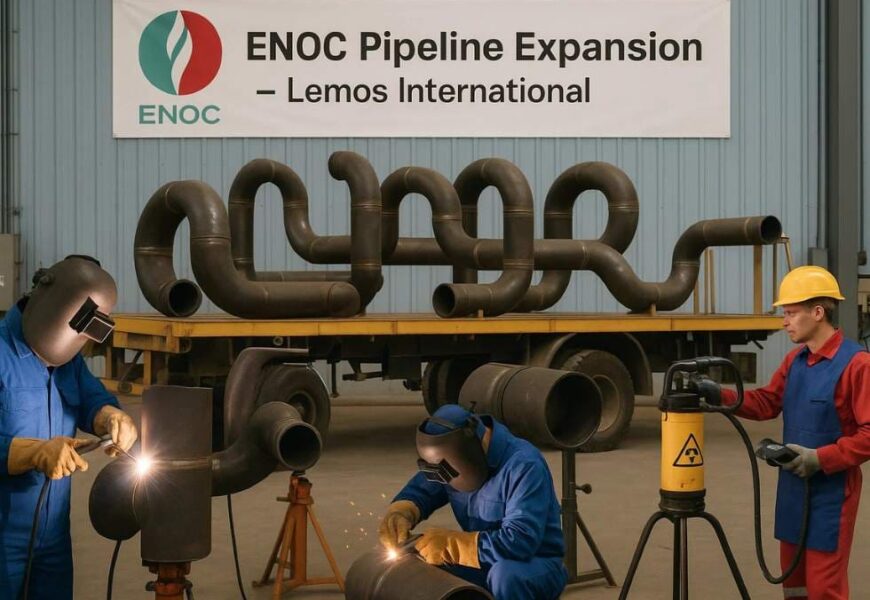

Lemos International successfully completed the fabrication and welding of a 12-kilometer pipeline for the ENOC Pipeline Expansion project. This critical infrastructure development was designed to enhance the transportation capacity of hydrocarbons across key regions in the UAE. Our scope included advanced pipe fabrication using GTAW (Gas Tungsten Arc Welding) and SMAW (Shielded Metal Arc Welding), along with rigorous hydrotesting and radiographic testing (RT) to ensure compliance with industry standards.

Our scope of work included:

- Pipe Fabrication: Precision cutting, beveling, and assembly of carbon steel pipes to meet ENOC’s stringent specifications.

- Advanced Welding Techniques: Utilized GTAW for root passes and SMAW for fill and cap passes, ensuring high-quality welds that met ASME and API standards.

- Radiographic Testing (RT): Conducted 100% RT inspection to achieve zero defects and secure full clearance from regulatory authorities.

- Hydrotesting: Performed pressure testing to verify the structural integrity and leak-free performance of the pipeline under operational conditions.

- Pre-Fabricated Spools: Manufactured pre-assembled spools in our workshop to minimize field welding time and improve efficiency.

The project was executed with an unwavering focus on quality, safety, and timely delivery, reinforcing Lemos International’s position as a leader in pipeline construction and maintenance.

Key Features of the Project

Advanced Welding Technologies

- Employed GTAW for precise root welding, ensuring clean, defect-free joints with minimal heat input.

- Used SMAW for subsequent passes, delivering robust and durable welds capable of withstanding high-pressure environments.

- Achieved a 0% weld rejection rate through meticulous quality control and skilled craftsmanship.

Pre-Fabricated Spool Integration

- Manufactured large sections of the pipeline as pre-fabricated spools in our controlled workshop environment.

- Transported and installed these spools on-site, significantly reducing field welding time and improving overall project efficiency.

Stringent Quality Assurance

- Conducted 100% radiographic testing (RT) on all welds to detect internal defects and ensure compliance with ENOC’s quality requirements.

- Performed visual inspections, ultrasonic testing, and dye penetrant testing as additional layers of quality assurance.

Hydrostatic Pressure Testing

- Pressurized the pipeline to 1.5 times its design pressure to validate its strength and leak-tightness.

- Monitored test results in real-time to identify and rectify any anomalies promptly.

Safety Compliance

- Adhered to strict HSE protocols, including hot work permits, confined space entry procedures, and fall protection measures.

- Deployed certified welders and inspectors trained to handle hazardous materials safely.

What is Challenge for client?

Challenge 1: Minimizing Field Welding Time

Field welding is labor-intensive and prone to delays due to environmental factors such as weather and accessibility issues.

Solution:

We adopted a pre-fabrication strategy, manufacturing large pipeline spools in our workshop where conditions were controlled. These spools were then transported to the site for final assembly, reducing field welding time by over 30%.

Challenge 2: Achieving 0% Weld Rejection Rate

Maintaining a flawless welding record required exceptional skill and precision, especially given the stringent requirements of ENOC and regulatory bodies.

Solution:

Our team conducted extensive training programs for welders and implemented a rigorous QA/QC process. Every weld was inspected multiple times using various non-destructive testing methods, ensuring no defects went unnoticed.

Challenge 3: Ensuring 100% RT Clearance

Radiographic testing is a critical step in pipeline projects, but achieving full clearance can be challenging due to potential defects.

Solution:

We employed highly skilled radiographers and utilized advanced RT equipment to capture detailed images of every weld. Any minor imperfections were addressed immediately, ensuring 100% RT clearance without rework.

Outcome & Client Satisfaction

The successful completion of the ENOC Pipeline Expansion project highlights Lemos International’s expertise in delivering large-scale pipeline projects with uncompromising quality. Key achievements include:

- Flawless Execution: The entire 12km pipeline was fabricated and welded with a 0% weld rejection rate, setting a benchmark for excellence.

- Efficient Delivery: Pre-fabricated spools reduced field time significantly, allowing the project to be completed ahead of schedule.

- Regulatory Compliance: Full RT clearance and successful hydrotesting ensured compliance with ENOC’s stringent quality and safety standards.

- Operational Readiness: The pipeline was commissioned without any issues, enabling ENOC to expand its transportation capacity seamlessly.

ENOC expressed immense satisfaction with the outcome, commending our team’s technical expertise, commitment to quality, and ability to deliver under tight deadlines.

Why Choose Lemos International?

At Lemos International, we are dedicated to providing innovative and reliable solutions for pipeline fabrication, welding, and maintenance projects. Our core strengths include:

- Technical Excellence: With decades of experience in pipeline construction, we possess the expertise to handle even the most complex projects.

- Commitment to Safety: We prioritize safety at every stage, adhering to the highest HSE standards to protect workers and assets.

- Quality Assurance: Our rigorous QA/QC processes ensure that every weld, joint, and component meets or exceeds industry standards.

- Proven Track Record: Our portfolio includes numerous pipeline projects completed on time, within budget, and to the highest quality benchmarks.