Project Details

- HVAC & Electrical

- 15th June 2021

- Confidential Logistics Group

- HVAC, Electrical, MEP Contracting

Project Description

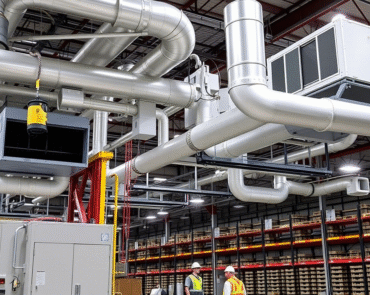

Lemos International is proud to have successfully delivered a comprehensive HVAC and electrical contracting solution for the Dubai Industrial Warehouse Complex, a state-of-the-art facility comprising five warehouse blocks located in Dubai Investment Park 2. The project exemplifies our commitment to delivering high-quality electromechanical services tailored to meet the unique requirements of industrial clients.

Our scope of work included:

- HVAC Systems: Design, supply, installation, and commissioning of galvanized iron (GI) ducting, chillers, air handling units (AHUs), rooftop condensing units, and associated piping systems.

- Electrical Systems: Complete electrical works encompassing power distribution, lighting, emergency backup systems, and fire alarm installations.

- MEP Coordination: Utilization of Building Information Modeling (BIM) technology to ensure seamless service coordination and eliminate clashes during construction.

The project was executed with precision and adherence to international standards, ensuring optimal performance, energy efficiency, and compliance with local regulations.

Key Features of the Project

Advanced HVAC Solutions

- Installation of high-efficiency chillers integrated into the central cooling system.

- Strategic placement of AHUs and rooftop condensing units to maximize airflow and temperature control across all warehouse blocks.

- Implementation of robust GI ducting systems designed for durability and minimal maintenance.

Comprehensive Electrical Infrastructure

- Reliable power distribution systems equipped with redundant circuits to ensure uninterrupted operations.

- Energy-efficient LED lighting solutions installed throughout the facility.

- Emergency backup systems, including generators and UPS units, to safeguard critical operations during power outages.

BIM-Driven MEP Coordination

- Leveraged advanced BIM tools to create clash-free designs, minimizing rework and ensuring smooth on-site execution.

- Enhanced collaboration between disciplines through 3D modeling, resulting in improved accuracy and faster project delivery.

Sustainability Focus

- Designed HVAC and electrical systems with sustainability in mind, incorporating energy-saving technologies to reduce the facility’s carbon footprint.

- Compliance with LEED (Leadership in Energy and Environmental Design) principles where applicable.

What is Challenge for client?

Challenge 1: Tight Deadlines

Given the client’s operational timelines, the project required fast-track execution without compromising quality or safety.

Solution:

We implemented an accelerated procurement strategy, working closely with suppliers to expedite material deliveries. Our experienced project management team ensured that resources were allocated efficiently, enabling us to complete the installation three weeks ahead of schedule.

Challenge 2: Complex MEP Coordination

The integration of multiple services within limited ceiling voids posed significant coordination challenges.

Solution:

By employing cutting-edge BIM software, we created detailed 3D models that identified potential clashes before construction began. This proactive approach eliminated conflicts during installation, saving time and reducing costs.

Challenge 3: On-Site Constraints

Limited access to certain areas of the site due to ongoing civil works impacted our ability to execute tasks concurrently.

Solution:

Our skilled workforce adapted quickly by adopting modular assembly techniques off-site. Pre-fabricated components were then transported to the site for final assembly, ensuring minimal disruption to the overall project timeline.