Project Details

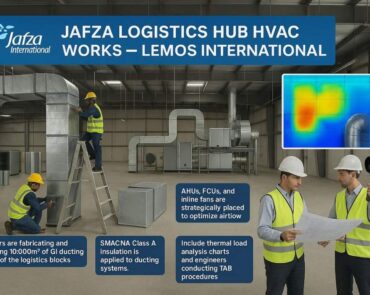

- JAFZA Logistics Hub

- 24th March 2024

- Global Logistics Solutions FZE

- HVAC Systems, Ducting, AHUs, FCUs, Thermal Load Analysis

Project Description

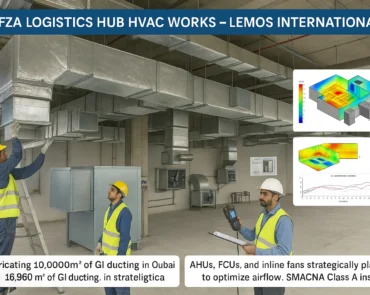

Lemos International successfully delivered a complete HVAC system for the JAFZA Logistics Hub, a state-of-the-art facility comprising four logistics blocks. The project encompassed static pressure and thermal load analysis, fabrication and installation of 10,000m² of galvanized iron (GI) ducting, and the installation of air handling units (AHUs), fan coil units (FCUs), inline fans, and SMACNA Class A insulation. Our team completed the project within three months, ensuring optimal climate control and energy efficiency across all logistics blocks.

Our scope of work included:

- Thermal Load Analysis: Conducted detailed thermal load calculations to determine cooling requirements for each logistics block.

- Static Pressure Analysis: Performed static pressure analysis to design an efficient ducting system that minimized energy losses.

- Duct Fabrication & Installation: Fabricated and installed 10,000m² of GI ducting, adhering to SMACNA standards for durability and performance.

- HVAC Equipment Installation: Installed AHUs, FCUs, inline fans, and other HVAC components to ensure consistent airflow and temperature regulation.

- Insulation Application: Applied SMACNA Class A insulation to ducting systems to prevent heat loss and condensation.

- Testing, Adjusting, and Balancing (TAB): Conducted TAB to verify system performance and ensure compliance with design specifications.

The project was executed with meticulous attention to detail, adhering to international standards and delivering a reliable, efficient, and sustainable HVAC solution for the logistics hub.

Key Features of the Project

Comprehensive Thermal Load Analysis

- Conducted detailed thermal load calculations to determine cooling requirements for each logistics block, ensuring optimal HVAC system sizing and performance.

- Factored in variables such as building orientation, occupancy levels, and equipment heat loads to achieve precise results.

Static Pressure Optimization

- Performed static pressure analysis to design a ducting system that minimized resistance and energy consumption while maintaining consistent airflow.

- Utilized computational fluid dynamics (CFD) simulations to validate duct design and eliminate potential bottlenecks.

High-Quality Duct Fabrication & Installation

- Fabricated 10,000m² of GI ducting in-house using advanced machinery to ensure precision and durability.

- Installed ducting systems with seamless joints and secure connections to prevent air leaks and ensure long-term reliability.

Advanced HVAC Equipment Integration

- Installed AHUs, FCUs, and inline fans strategically to optimize airflow distribution and temperature regulation across all logistics blocks.

- Integrated smart controls for remote monitoring and adjustment of HVAC parameters, enhancing operational efficiency.

SMACNA Class A Insulation

- Applied SMACNA Class A insulation to all ducting systems, ensuring superior thermal performance and condensation prevention.

- Conducted visual inspections and thermal imaging tests to verify insulation integrity.

Rigorous Testing, Adjusting, and Balancing (TAB)

- Conducted TAB procedures to verify airflow rates, temperature differentials, and system balance, ensuring compliance with design specifications.

- Documented TAB reports meticulously, providing traceability and assurance of system performance.

What is Challenge for client?

Challenge 1: Fabricating and Installing 10,000m² of Ducting

Handling such a large volume of ducting required careful planning to avoid delays and ensure quality.

Solution:

We pre-fabricated ducting components in our workshop using automated machinery, ensuring precision and consistency. On-site installation was executed in phases to minimize disruptions and maintain progress.

Challenge 2: Ensuring Consistent Airflow Across Large Spaces

Achieving uniform airflow in expansive logistics blocks posed significant challenges due to varying thermal loads and structural layouts.

Solution:

Our team conducted CFD simulations to design duct layouts that ensured balanced airflow distribution. Adjustable dampers were installed to fine-tune airflow during commissioning.

Challenge 3: Meeting Tight Deadlines

Completing the project within three months required efficient resource allocation and execution.

Solution:

We implemented extended shifts and deployed additional manpower where necessary. Daily progress reviews ensured that tasks were completed on schedule without compromising quality.

Challenge 4: Verifying System Performance via TAB

Conducting TAB for a large-scale HVAC system required rigorous testing and documentation to ensure compliance with design specifications.

Solution:

We employed certified TAB technicians equipped with advanced tools to measure airflow rates, temperature differentials, and system balance. Test results were documented meticulously and cross-verified for accuracy.

Outcome & Client Satisfaction

The successful completion of the JAFZA Logistics Hub – Ducting & HVAC Works project highlights Lemos International’s expertise in delivering large-scale HVAC solutions under challenging conditions. Key achievements include:

- On-Time Delivery: The project was commissioned within three months, allowing Global Logistics Solutions FZE to commence operations seamlessly.

- Energy Efficiency: The optimized ducting system and advanced HVAC equipment ensured minimal energy consumption while maintaining optimal climate control.

- Verified Performance: Rigorous TAB procedures validated system performance, ensuring compliance with design specifications and client expectations.

- Client Satisfaction: Global Logistics Solutions FZE expressed immense satisfaction with the outcome, praising our technical expertise, proactive approach, and ability to deliver high-quality results within tight deadlines.

Why Choose Lemos International?

At Lemos International, we specialize in providing world-class HVAC and ducting solutions for commercial, industrial, and logistics facilities. Our core strengths include:

- Proven Expertise in HVAC Systems: With decades of experience in designing, fabricating, and installing HVAC systems, we possess the knowledge and skills to tackle even the most complex projects.

- Commitment to Quality: We adhere to the highest industry standards, leveraging advanced technologies and best practices to deliver durable, long-lasting systems.

- Focus on Sustainability: Our designs prioritize energy efficiency and environmental sustainability, reducing operational costs and minimizing carbon footprints.

- Proven Track Record: Our portfolio includes numerous HVAC projects completed on time, within budget, and to the highest quality standards.