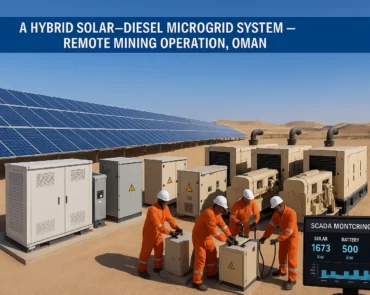

Project Details

- Hybrid Solar-Diesel Microgrid Installation

- 15th June 2022

- Private Utility Developer

- Solar PV Array, Hybrid Microgrid, SCADA Monitoring

Project Description

Lemos International is proud to have successfully delivered a comprehensive HVAC and electrical contracting solution for the Dubai Industrial Warehouse Complex, a state-of-the-art facility comprising five warehouse blocks located in Dubai Investment Park 2. The project exemplifies our commitment to delivering high-quality electromechanical services tailored to meet the unique requirements of industrial clients.

Our scope of work included:

- HVAC Systems: Design, supply, installation, and commissioning of galvanized iron (GI) ducting, chillers, air handling units (AHUs), rooftop condensing units, and associated piping systems.

- Electrical Systems: Complete electrical works encompassing power distribution, lighting, emergency backup systems, and fire alarm installations.

- MEP Coordination: Utilization of Building Information Modeling (BIM) technology to ensure seamless service coordination and eliminate clashes during construction.

The project was executed with precision and adherence to international standards, ensuring optimal performance, energy efficiency, and compliance with local regulations.

Key Features of the Project

Advanced HVAC Solutions

- Installation of high-efficiency chillers integrated into the central cooling system.

- Strategic placement of AHUs and rooftop condensing units to maximize airflow and temperature control across all warehouse blocks.

- Implementation of robust GI ducting systems designed for durability and minimal maintenance.

Comprehensive Electrical Infrastructure

- Reliable power distribution systems equipped with redundant circuits to ensure uninterrupted operations.

- Energy-efficient LED lighting solutions installed throughout the facility.

- Emergency backup systems, including generators and UPS units, to safeguard critical operations during power outages.

BIM-Driven MEP Coordination

- Leveraged advanced BIM tools to create clash-free designs, minimizing rework and ensuring smooth on-site execution.

- Enhanced collaboration between disciplines through 3D modeling, resulting in improved accuracy and faster project delivery.

Sustainability Focus

- Designed HVAC and electrical systems with sustainability in mind, incorporating energy-saving technologies to reduce the facility’s carbon footprint.

- Compliance with LEED (Leadership in Energy and Environmental Design) principles where applicable.

What is Challenge for client?

Challenge 1: Forced Outage Conditions

The emergency nature of the repair required rapid mobilization and execution under tight deadlines.

Solution:

Our team worked extended shifts and deployed additional manpower to ensure timely completion without compromising quality.

Challenge 2: Complex Hot Gas Path Repairs

Repairing the hot gas path components required specialized skills and equipment.

Solution:

We utilized certified tools and employed experienced technicians trained in gas turbine repairs to ensure precision and reliability.

Challenge 3: Ensuring Compliance

Obtaining compliance certification required rigorous testing and documentation.

Solution:

We conducted thorough trial runs and documented all findings meticulously, ensuring full compliance with regulatory standards.

Outcome & Client Satisfaction

The successful completion of the Gas Turbine Plant Emergency Repair underscores Lemos International’s ability to deliver critical repairs under extreme conditions. Key achievements include:

- Re-Energization Within 12 Days: The plant was restored to operation within the tight deadline, minimizing downtime and financial losses.

- Compliance Certification: Obtained full compliance certification, reflecting our adherence to industry standards.

- Operational Reliability: Repairs ensured long-term reliability and improved turbine performance.

- Client Trust: The confidential power utility expressed immense satisfaction with the outcome, praising our responsiveness and technical expertise.